The food and beverage industry relies on precise and validated methods to ensure product safety, quality, and shelf stability. Among the most critical of these methods is thermal food processing, a fundamental and scientifically-driven approach to preservation. For laboratory professionals, a deep understanding of thermal treatments is not merely an academic exercise; it is an essential competency for product development, quality assurance, and regulatory compliance.

What is Thermal Processing?

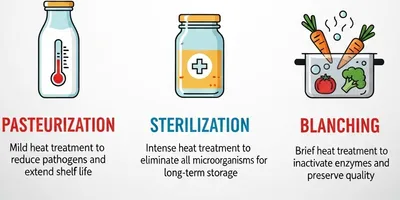

Thermal food processing refers to any food preservation technique that uses heat to inactivate microorganisms and enzymes. The primary goal is to ensure the product is safe for consumption and to maintain its quality over time. These processes are not one-size-all; they are carefully calibrated based on the specific product's composition, the types of microorganisms present, and the desired outcome. The application of heat must be sufficient to achieve the required lethality but not so excessive as to cause detrimental changes to the food's sensory attributes, such as flavor, color, or texture. The three main categories of thermal food processing—pasteurization, sterilization, and blanching—each have distinct purposes and operational parameters, making their correct application a key focus of food science and technology.

Pasteurization Principles and Applications

Pasteurization is a mild thermal food processing method designed to reduce the number of viable pathogens to a safe level, thus extending shelf life without causing significant changes to the food's organoleptic properties. It is a non-sterilizing process, meaning it does not kill all microorganisms, and the product typically requires refrigeration to prevent the growth of surviving spoilage microbes.

The effectiveness of pasteurization is measured by the destruction of a specific, heat-resistant pathogen, often Coxiella burnetii in milk, which serves as an indicator for other pathogens. The lethal effect of heat on microorganisms is characterized by the D-value, or decimal reduction time, which represents the time required to destroy 90% (one log cycle) of a microbial population at a given temperature. The Z-value describes the temperature change needed to alter the D-value by a factor of 10.

Common pasteurization methods include:

- High-Temperature, Short-Time (HTST):

- Temperature & Time: Typically 71.5∘C for 15 seconds.

- Application: Widely used for milk, juice, and liquid eggs.

- Principle: Rapid heating and cooling in a plate or tubular heat exchanger. This method is energy-efficient and preserves a product's nutritional and sensory qualities.

- Vat Pasteurization (Low-Temperature, Long-Time):

- Temperature & Time: Typically 63∘C for 30 minutes.

- Application: Used for ice cream mix, certain dairy products, and small-batch processing.

- Principle: Heating a large volume of product in a jacketed vat. It is a slower process but suitable for products with high viscosity.

Sterilization Techniques for Food Safety

Unlike pasteurization, sterilization is a severe thermal food processing method that aims to create a commercially sterile product, meaning it is free of all pathogenic and spoilage microorganisms capable of growing under normal storage conditions. These products are shelf-stable and do not require refrigeration.

The effectiveness of sterilization is measured by the F-value, or lethal rate, which quantifies the total heat lethality received by a product. A common reference is the F0 value, which is defined as the equivalent time in minutes at a reference temperature of 121.1∘C to achieve the desired level of microbial inactivation.

Key sterilization methods include:

- Retort Processing:

- Principle: Involves sealing food in hermetically sealed containers (e.g., cans, jars) and subjecting them to high temperatures and pressures in a large pressure vessel known as a retort.

- Application: Used for low-acid foods (pH > 4.6), such as vegetables, meats, and ready meals, where the risk of Clostridium botulinum is significant.

- Ultra-High Temperature (UHT) Processing:

- Temperature & Time: Typically 135∘C to 150∘C for 1 to 2 seconds.

- Principle: This method uses rapid heating and cooling cycles, often in a continuous flow system, followed by aseptic packaging.

- Application: Common for milk, cream, and fruit juices. The short duration minimizes heat damage to the product while effectively sterilizing it.

Blanching: Pre-treatment and Quality Preservation

Blanching is a mild thermal food processing technique that serves as a critical pre-treatment step rather than a primary preservation method. Its main objective is to inactivate endogenous enzymes that can cause undesirable changes in color, flavor, texture, and nutritional value during subsequent freezing or dehydration.

The effectiveness of blanching is typically assessed by testing for the inactivation of a key indicator enzyme, most commonly peroxidase or catalase. If these heat-resistant enzymes are inactivated, it is assumed that other, less-resistant enzymes have also been destroyed.

Common blanching methods include:

- Hot Water Blanching:

- Principle: Immersing food, such as fruits or vegetables, in hot water at temperatures ranging from 85∘C to 100∘C for a specific time.

- Advantages: Simple and cost-effective.

- Disadvantages: Can lead to the leaching of water-soluble nutrients and flavors.

- Steam Blanching:

- Principle: Exposing food to high-temperature steam.

- Advantages: Better retention of water-soluble nutrients and less product weight loss compared to hot water blanching.

- Application: Used for products that may become waterlogged, such as mushrooms and leafy greens.

Thermal Processing Equipment and Instrumentation

The successful application of any thermal food processing method depends on the use of precisely controlled equipment. Laboratory and pilot plant settings require robust instrumentation to accurately measure and record critical processing parameters.

- Heat Exchangers:These are a class of equipment used for continuous thermal processing of liquid products.

- Plate Heat Exchangers: Composed of a series of corrugated plates that create channels for product and heating/cooling media. They are highly efficient and suitable for low-viscosity liquids like milk.

- Tubular Heat Exchangers: Consist of a tube-in-tube or shell-and-tube design, suitable for more viscous products or those containing particulates.

- Retorts:These are large pressure vessels for the sterilization of packaged products.

- Static Retorts: The product remains stationary during the process.

- Agitating Retorts: The product and its container are agitated to improve heat penetration, which is especially beneficial for viscous or particulate-containing foods.

- Instrumentation and Validation:The integrity of thermal food processing is confirmed through rigorous validation. Key instruments include:

- Thermocouples and Resistance Temperature Detectors (RTDs): These sensors are placed at the cold spot of the product to ensure that the slowest-heating point receives the required thermal treatment.

- Pressure Transducers: Critical for controlling pressure in retort processing to prevent container damage.

- Data Loggers: Used to record temperature and pressure data throughout the process, providing an auditable record for regulatory agencies and quality assurance protocols.

Advancing Food Safety Through Precise Thermal Processing

The science of thermal food processing represents a cornerstone of modern food manufacturing, blending microbiology, engineering, and chemistry to deliver safe, high-quality, and shelf-stable products. While pasteurization, sterilization, and blanching each serve distinct purposes, they collectively form a comprehensive strategy for product preservation. For the laboratory professional, understanding these processes, from their fundamental kinetics to the instrumentation used for their validation, is essential for ensuring consumer safety and maintaining product integrity. As technology evolves, so too will thermal food processing methods, but their core principles will remain foundational to the food industry.

Frequently Asked Questions about Thermal Food Processing

What is the primary difference between pasteurization and sterilization?

The primary difference lies in the severity of the heat treatment and the resulting product's shelf stability. Pasteurization is a mild heat process that reduces pathogens and requires refrigeration, while sterilization is a severe heat process that eliminates all microorganisms and results in a shelf-stable product.

How is thermal processing validated in a laboratory setting?

Thermal food processing is validated by measuring the temperature at the "cold spot" (the slowest-heating point) of the product within its container. This is typically done using thermocouples and data loggers to ensure the required temperature-time combination is achieved.

What is the significance of the Z-value in thermal processing?

The Z-value is a critical kinetic parameter that indicates the change in temperature required to cause a tenfold change in a microorganism's D-value (decimal reduction time). A low Z-value indicates high heat resistance and requires more precise temperature control.

Does thermal food processing affect nutritional value?

Yes, all thermal food processing can cause some degree of nutrient loss, particularly for heat-sensitive vitamins like Vitamin C and some B vitamins. The goal is to optimize the process to minimize these losses while ensuring food safety.