How It Works

Problem: With their critical needs for indoor air quality, power, temperature, humidity and other environmental conditions, labs traditionally have had a difficult time balancing the growing pressures for energy efficiency with the technical requirements of the required functionality within the facility.

Gas generators have become an alternative to high-pressure gas cylinders for supplying laboratory applications with high purity hydrogen, nitrogen, and zero-air. Until now, there has been no generator option for supplying high purity oxygen. Small pressure swing adsorption (PSA)-based oxygen generators are available for medical applications but do not offer the high purity generally required in the laboratory.

Problem: Bringing samples into a mineralized state is usually the first step for performing accurate inorganic analysis, aka metals trace analysis. This conversion of a usually non-homogenous insoluble mixture into a representative, homogenous aqueous solution using heat and acids is usually a prerequisite for further analysis work with spectroscopic or chromatographic techniques.

Problem: Detecting impurities in any chemical reaction has always been important to the chemist and it is becoming increasingly important to detect those present at low levels, (e.g. 0.5%).

Problem: Liquid retention in pipette tips and interaction between the materials with which the tip is made and the sample it contains are a great concern. Sample loss percentage and the subsequent cost for purchasing additional sample becomes significantly more important when expensive reagents such as antibodies and siRNA inhibitors are being pipetted.

Problem: ELISA assays are a workhorse assay used in pharmaceutical research and molecular diagnostic labs. This assay can be a high-volume service area for contract labs. However, many IVD labs and CROs have difficulty in costeffectively scaling their ELISA workflow to meet customer demand. This simple assay becomes deceptively complex: time sensitive steps and subtle workflow changes between different tests can be challenging to process as throughput increases. Reagent costs can cut further into tight operating margins. At some point manual processing becomes too challenging from an IVD compliance and operational perspective. Automating the laboratory’s workflow is the answer—but it can seem difficult to implement and expensive.

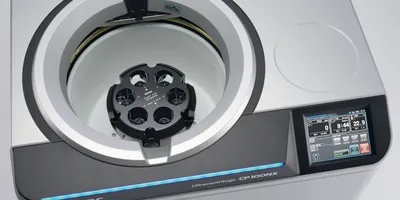

Problem: While laboratory instruments have become faster and more automated to increase productivity, sample preparation has continued to remain a bottleneck and source of variability for most labs. The complexity and variety of samples that typically pass through labs makes this area one of the most difficult to automate.