The evolution of aerospace technology demands materials that can withstand increasingly extreme conditions. As traditional metallic superalloys reach their thermodynamic limits, a new class of aerospace materials is required to operate at higher temperatures without extensive cooling. Ceramic matrix composites (CMCs) are a transformative solution. These engineered materials, which consist of a ceramic fiber reinforcement embedded within a ceramic matrix, overcome the inherent brittleness of monolithic ceramics. The resulting combination of fracture toughness, damage tolerance, and high-temperature resistance makes CMC a key enabler for next-generation engines and vehicles. These lightweight composites and other advanced high-temperature materials are essential for achieving unprecedented levels of efficiency, performance, and durability in aerospace design.

Understanding the Science of Ceramic Matrix Composites

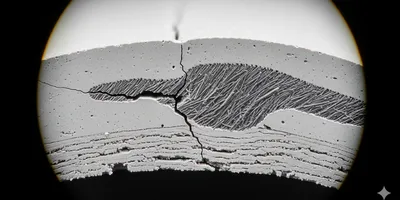

The core of a ceramic matrix composites' superior performance lies in its ability to manage and redirect cracks. Unlike brittle monolithic ceramics, which propagate a single crack path to failure, CMCs utilize a mechanism known as "crack deflection" or "fiber bridging." When a crack forms in the ceramic matrix, it encounters the reinforcing ceramic fibers. Instead of fracturing the fiber, the crack is diverted along the interface between the fiber and the matrix. This process consumes significant energy, effectively toughening the material. This behavior is what makes CMCs an exceptionally damage-tolerant material system.

The design of CMCs is a delicate balance of material properties. The fibers must have high tensile strength and a higher fracture toughness than the matrix, and they must be chemically stable at the operating temperature. Common fiber materials include silicon carbide (SiC) and alumina (Al2O3). The matrix, typically also SiC or a similar ceramic, serves to hold the fibers in place and transfer the load to the reinforcement. An interphase layer is often deliberately introduced between the fiber and the matrix to promote this crack deflection mechanism.

Component | Function | Typical Materials |

|---|---|---|

Fibers | Reinforcement; provides strength and crack resistance | SiC, Al2O3, Carbon |

Matrix | Encapsulates fibers; transfers load; provides environmental protection | SiC, Al2O3, Silicon Nitride (Si3N4) |

Interphase | Weak interface to promote crack deflection | Pyrolytic Carbon (PyC), Boron Nitride (BN) |

This complex architecture is what differentiates CMCs from other high-temperature materials. Their unique failure mode, which is more akin to a graceful degradation than a sudden, catastrophic break, makes them predictable and safer for critical aerospace components.

Unlocking Performance with High-Temperature Materials

One of the most significant advantages of ceramic matrix composites is their ability to operate at temperatures exceeding the melting points of conventional metallic alloys. This single property has a cascading effect on engine design and performance. By allowing hotter internal temperatures, engines can achieve greater thermodynamic efficiency, leading to reduced fuel consumption and lower emissions. The removal of or reduction in cooling air, which is typically bled from the compressor and reduces engine thrust, further enhances efficiency and power.

CMCs are currently being adopted for a variety of critical components in commercial and military jet engines.

- Turbine Blades and Vanes: These parts endure the highest temperatures within the engine. Replacing nickel superalloys with CMCs can increase the operating temperature by several hundred degrees, boosting performance.

- Combustor Liners: The liners of the combustion chamber must withstand extreme heat and pressure. CMCs provide a durable and lightweight alternative to traditional materials.

- Nozzles: CMC nozzles in rocket engines can operate at higher temperatures without active cooling, reducing system complexity and weight.

- Hypersonic Vehicle Leading Edges and Heat Shields: The immense friction generated by high-speed flight creates temperatures that would melt conventional metals. CMCs are key aerospace materials for these applications, providing necessary thermal protection.

The use of CMCs in these components directly translates to significant improvements in engine performance, durability, and a reduction in maintenance cycles.

The Role of Lightweight Composites in Aerospace

In the aerospace industry, every kilogram of weight saved results in substantial gains in fuel efficiency, payload capacity, and range. This is where lightweight composites and CMCs in particular, prove invaluable. A comparison of density reveals the immense potential of CMCs. While nickel-based superalloys have densities ranging from 7.5 to 9.5 g/cm3, silicon carbide CMCs possess a density of approximately 3.2 g/cm3. This translates to a weight reduction of over 50% for equivalent-sized components, a truly revolutionary figure for engine designers.

This weight saving is not merely a side benefit; it is an economic and performance imperative. A lighter engine requires less fuel to achieve the same thrust, reducing operational costs and lowering carbon emissions. For long-haul commercial flights, the cumulative effect of these savings over thousands of flight hours is immense. In military applications, the increased thrust-to-weight ratio provided by lightweight composites allows for superior maneuverability and performance. The synergy between high-temperature resistance and low density makes CMCs a game-changer for next-generation aircraft and spacecraft design. The integration of these materials represents a paradigm shift from a metal-centric approach to a composite-centric one, optimizing systems from the ground up for maximum efficiency.

Advanced Characterization of Ceramic Matrix Composites

For the laboratory professional, the development and deployment of ceramic matrix composites hinges on rigorous characterization and quality control. The complex, multi-phase nature of CMCs requires a sophisticated suite of analytical and mechanical testing techniques to ensure performance and reliability.

Non-destructive testing (NDT) methods are crucial for detecting internal defects such as porosity, microcracks, and delamination without damaging the component. X-ray computed tomography (CT) scanning and ultrasonic testing are used to create detailed 3D maps of the internal structure, identifying anomalies that could compromise the material's integrity. These methods are vital for both the research and development phase and for routine inspections of finished parts.

Mechanical testing provides essential data on the material’s structural performance under simulated operating conditions.

Mechanical testing is essential to discover the structural properties of CMCs.

GEMINI (2025)

- Tensile Testing: Measures the material's strength and elongation under tension, providing a key indicator of its fracture toughness.

- Creep and Fatigue Testing: Evaluates the material's resistance to deformation and failure under sustained high temperature and cyclical loads, respectively. These tests are particularly important for turbine engine components.

- Thermal Shock and Oxidation Testing: Assesses the material’s durability when subjected to rapid temperature changes and harsh oxidizing environments, such as those found in a combustor.

Microstructural analysis, typically performed using scanning electron microscopy (SEM) and transmission electron microscopy (TEM), allows for the visualization of the fiber-matrix interface and the detection of microscopic damage. This level of detailed analysis provides critical feedback for refining material composition and manufacturing processes. The meticulous characterization of ceramic matrix composites ensures that they meet the stringent safety and performance standards of the aerospace industry.

The Future of Aerospace Materials: The Role of CMCs

The journey of ceramic matrix composites from a research concept to a commercially viable aerospace material is a testament to decades of scientific and engineering effort. By addressing the fundamental limitations of monolithic ceramics—their brittleness and lack of damage tolerance—CMCs have emerged as the premier solution for applications operating at the bleeding edge of thermodynamics. Their unique combination of high-temperature resistance, lightweight properties, and durability positions them as a cornerstone of future aerospace design.

Ongoing research is focused on further enhancing CMC properties, including improving environmental resistance, reducing manufacturing costs, and exploring new fiber and matrix material combinations. As the aerospace industry continues its push for greater efficiency and performance, the role of CMCs will only grow in importance. For lab professionals, the ability to analyze, test, and characterize these advanced materials is crucial for ensuring the safety and success of the next generation of aircraft and spacecraft. The future of flight is not metallic; it is composite.

Frequently Asked Questions About Ceramic Matrix Composites

What is the primary advantage of CMCs over monolithic ceramics?The main advantage is fracture toughness. By incorporating a reinforcing ceramic fiber phase, CMCs prevent the catastrophic failure seen in brittle monolithic ceramics, offering greater reliability and durability.

How do ceramic matrix composites contribute to fuel efficiency?CMCs are significantly lighter than the metallic superalloys they replace. This weight reduction directly translates to lower fuel consumption for equivalent thrust, leading to substantial operational cost savings and reduced emissions.

What are common examples of CMC applications in modern aircraft?CMCs are used in jet engine components such as turbine blades, combustor liners, and nozzles. They are also integral to the thermal protection systems and leading edges of high-speed and hypersonic vehicles.

What is the typical composition of a CMC?A typical ceramic matrix composites consists of a ceramic fiber (e.g., silicon carbide or alumina) embedded in a ceramic matrix (e.g., silicon carbide or silicon nitride). An interphase layer is often included to facilitate load transfer and crack deflection.