The modern materials science laboratory is a hub of innovation, where foundational research translates into advanced technologies. From developing next-generation alloys to synthesizing novel polymers, the work conducted in these environments is pivotal for a wide array of industries, including aerospace, electronics, and medicine. The success of this critical research is not solely dependent on the technical prowess of the scientists; it is fundamentally linked to the underlying management infrastructure. Effective materials science lab management is the essential framework that ensures operational continuity, data integrity, and research reproducibility. Without a robust management system, a laboratory risks inefficiencies, compromised results, and potential safety hazards. This article examines the core principles and best practices for managing a materials science laboratory, focusing on the strategic and operational pillars that enable scientific excellence and drive innovation.

Foundational Principles of Lab Operations

The backbone of any high-performing laboratory is a set of well-defined and consistently executed lab operations. These principles govern the daily activities that keep research moving forward smoothly and predictably. Strategic oversight of these operations ensures that resources are utilized efficiently and that the laboratory remains a productive and reliable environment.

Inventory and Supply Chain Management

Efficient inventory management is critical to avoiding research delays and controlling costs. It requires a systematic approach to tracking chemicals, raw materials, and consumables. A digital inventory system, such as a Laboratory Information Management System (LIMS), is highly effective for this purpose. Such systems enable real-time tracking of stock levels, expiration dates, and usage patterns. A proactive reordering process, triggered by pre-set minimum stock levels, prevents shortages of essential materials.

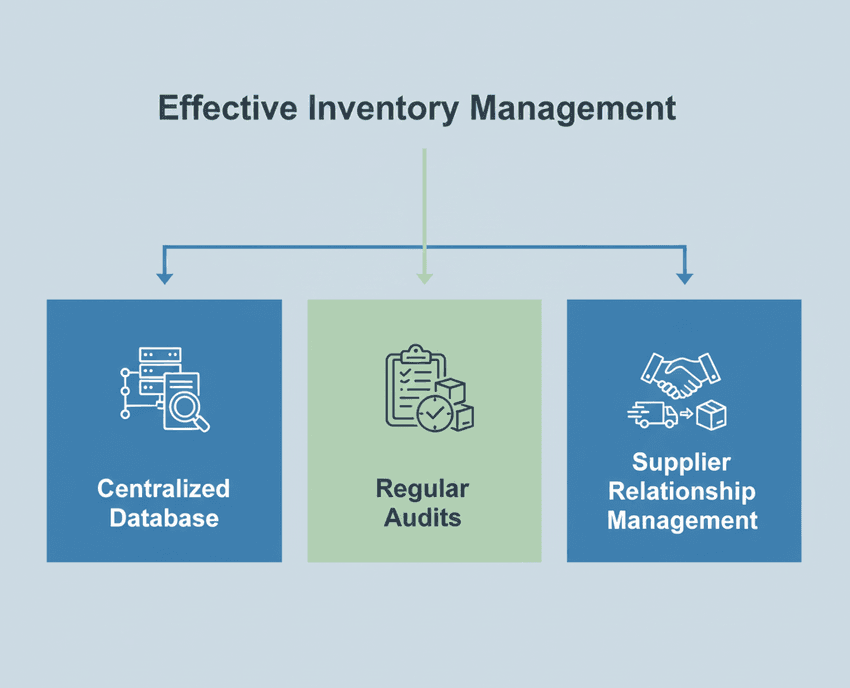

Key components of effective inventory management include:

Effective inventory management requires a multi-pronged approach.

GEMINI (2025)

Centralized Database: A single, accessible database for all lab materials, including safety data sheets (SDS) and storage requirements.

Regular Audits: Periodic physical counts to reconcile with the digital inventory, identifying discrepancies and reducing waste.

Supplier Relationship Management: Building strong relationships with vendors to secure reliable supply, favorable pricing, and timely delivery of specialized materials.

Equipment Maintenance and Calibration

Precision and accuracy are paramount in materials science. Equipment, from scanning electron microscopes (SEMs) and X-ray diffraction (XRD) systems to rheometers and universal testing machines, must be meticulously maintained and calibrated. A well-structured maintenance schedule prevents unexpected downtime and ensures the integrity of experimental data. This involves both routine internal checks and professional servicing. A comprehensive logbook for each instrument, documenting all maintenance, repairs, and calibration records, is a non-negotiable part of good lab operations. The log should include a history of usage, any observed issues, and a schedule for future servicing. Adherence to manufacturer specifications for calibration intervals is a standard practice that underpins data reliability.

Standard Operating Procedures (SOPs)

SOPs are the definitive guide for all laboratory tasks and processes. They standardize experimental procedures, equipment use, and data recording, eliminating variability and ensuring reproducibility across multiple users. Each SOP should be clear, concise, and easily accessible. They are essential for training new personnel and for maintaining consistency in long-term research projects. A robust system for SOP revision control ensures that all staff members are working from the most current protocols.

Strategic Research Management and the Materials Science Project Lifecycle

Beyond daily tasks, the success of a materials science laboratory hinges on its approach to research management. This involves the strategic planning, execution, and evaluation of projects to align with organizational goals and scientific objectives.

The materials research project lifecycle can be broken down into distinct phases:

- Phase 1: Conceptualization and Proposal. This initial phase involves defining the research problem, conducting a thorough literature review, and developing a detailed project plan. This plan should include a clear hypothesis, a methodology, resource requirements, and a timeline with milestones.

- Phase 2: Experimentation and Data Collection. This is the core experimental phase. Effective research management at this stage requires a meticulous approach to data logging and experiment tracking. A digital laboratory notebook (ELN) can be a powerful tool for this, providing a searchable, centralized repository for all experimental data, observations, and preliminary analyses.

- Phase 3: Data Analysis and Interpretation. Raw data from instruments must be processed and analyzed to derive meaningful insights. This often involves specialized software and computational resources. A standardized data analysis workflow ensures that all data is handled consistently, and a clear data provenance trail is maintained.

- Phase 4: Reporting and Publication. The final phase involves disseminating the research findings through internal reports, presentations, and peer-reviewed publications. The quality of the final report is directly tied to the rigor of the data collection and analysis phases, underscoring the importance of meticulous research management from the project's inception.

Streamlining the Materials Science Workflow

A well-optimized materials science workflow is characterized by its seamless flow from sample preparation to final characterization and data interpretation. Optimizing this workflow reduces bottlenecks, accelerates discovery, and improves overall efficiency. .

Sample Preparation and Handling

The integrity of a materials science experiment begins with proper sample preparation. This stage requires precision, cleanliness, and adherence to specific protocols. Contamination or improper handling at this point can invalidate all subsequent data. A clear system for sample identification, tracking, and storage is essential.

Instrumentation and Characterization

Materials science is an instrument-heavy discipline. The workflow involves a sequence of characterization techniques to understand a material's structure, composition, and properties. A streamlined process might involve:

- Initial Screening: Techniques like optical microscopy or Fourier-transform infrared spectroscopy (FTIR) for quick, non-destructive initial analysis.

- Structural Analysis: Advanced techniques such as X-ray diffraction (XRD) and transmission electron microscopy (TEM) to determine crystal structure and defects.

- Compositional Analysis: Tools like energy-dispersive X-ray spectroscopy (EDS) or X-ray photoelectron spectroscopy (XPS) for elemental and chemical analysis.

- Mechanical and Physical Testing: Universal testing machines for mechanical properties (e.g., tensile strength) and thermal analyzers (e.g., differential scanning calorimetry) for physical properties.

Data Management and Analysis

The sheer volume of data generated in a materials science workflow necessitates a robust data management strategy. All raw data, processed data, and analysis results must be stored in a centralized, secure location with appropriate backups. A standardized data schema for file naming and organization facilitates collaboration and ensures that data remains accessible and understandable for future use.

Upholding the Highest Standards in Lab Safety

A paramount responsibility in a materials science laboratory is ensuring the health and safety of all personnel. Comprehensive lab safety protocols are non-negotiable and are foundational to responsible materials science lab management.

Hazard Communication and Training

All personnel must be thoroughly trained on the hazards associated with the materials and equipment they handle. This includes understanding chemical properties, reactivity, and proper handling procedures as outlined in SDS. Regular training sessions on emergency response, fire extinguisher use, and spill cleanup are mandatory. The training program should be documented, with records of attendance and competency.

Personal Protective Equipment (PPE)

The use of appropriate PPE is a first line of defense against workplace hazards. A clear policy on required PPE for specific tasks and areas is essential. This includes, but is not limited to:

- Eye Protection: Safety goggles or face shields, especially when handling chemicals or operating machinery.

- Hand Protection: Gloves suitable for the specific chemicals being handled (e.g., nitrile, latex, neoprene).

- Body Protection: Lab coats or aprons to protect clothing and skin from spills.

- Respiratory Protection: Respirators or fume hoods when working with volatile or hazardous substances.

Emergency Procedures and Waste Disposal

A clear and well-communicated set of emergency procedures is vital. This includes the location of safety showers, eyewash stations, fire extinguishers, and emergency exits. Drills should be conducted periodically to ensure all staff are familiar with the protocols. Proper chemical waste disposal is a legal and ethical requirement. Waste streams must be segregated, labeled correctly, and stored securely until collected by a licensed disposal company. This is a critical component of a proactive lab safety plan.

Mastering Materials Science Lab Management

Effective materials science lab management is an intricate discipline that extends far beyond simple administrative tasks. It is the strategic and operational engine that enables scientific discovery and ensures the integrity of research outcomes. The principles of sound lab operations, strategic research management, a streamlined materials science workflow, and an unwavering commitment to lab safety are not isolated functions; they are interconnected pillars that support the entire research ecosystem. A laboratory that invests in and systematically implements these best practices establishes a foundation for reproducibility, efficiency, and safety, thereby solidifying its position at the forefront of scientific innovation. Mastering these management principles is essential for any professional seeking to lead a successful and impactful materials science research program.

FAQ

What are the key challenges in materials science lab management?

Managing a materials science laboratory presents a unique set of challenges due to its multidisciplinary nature and the complexity of its research. One primary challenge is the capital-intensive nature of the required equipment and the high cost of specialized materials. This necessitates meticulous budgeting and financial oversight. Another significant challenge is data management; the sheer volume and diverse formats of data from various instruments require a robust system to ensure data integrity, accessibility, and long-term storage. Personnel management is also a critical factor, as coordinating the diverse expertise of chemists, physicists, and engineers requires clear communication and a cohesive organizational structure. These complexities underscore the importance of a comprehensive approach to materials science lab management.

How can digital tools improve lab operations and data management?

Digital tools have revolutionized modern lab operations by introducing unprecedented levels of efficiency and organization. Laboratory Information Management Systems (LIMS) are instrumental in automating sample tracking, managing workflows, and maintaining a centralized inventory. Electronic Laboratory Notebooks (ELNs) replace traditional paper notebooks, allowing for real-time data capture, easy searchability, and secure storage of experimental protocols and results. These tools facilitate better collaboration among researchers and provide a clear audit trail for all experiments. For data management, cloud-based storage solutions offer scalability and accessibility, while dedicated software can streamline data processing and analysis. The adoption of these digital platforms is a key step towards optimizing lab operations and data security.

What are the most important components of a robust lab safety program?

A robust lab safety program is built on a foundation of proactive measures and continuous improvement. The most critical component is comprehensive training; all personnel must receive regular, documented instruction on chemical handling, equipment-specific safety protocols, and emergency procedures. The implementation of clear hazard communication standards, including proper labeling and readily available Safety Data Sheets (SDS), is also non-negotiable. Furthermore, a thorough system for managing and enforcing the use of appropriate Personal Protective Equipment (PPE) for every task is essential. Finally, a proactive culture of safety, where regular audits are conducted and safety concerns are addressed without delay, is crucial. This proactive approach to lab safety is the cornerstone of responsible scientific research.

How does effective research management influence the pace of discovery?

Effective research management is a direct catalyst for accelerating scientific discovery. By implementing a structured approach to project planning, a laboratory can more efficiently allocate resources and identify potential bottlenecks before they cause delays. A clear research plan, with well-defined milestones and objectives, keeps the team focused and aligned. Furthermore, robust data management and analysis protocols ensure that experimental data is not only captured accurately but is also processed and interpreted in a timely manner. This minimizes time spent on troubleshooting and rework, allowing researchers to concentrate on high-impact tasks. In essence, strategic research management transforms a series of experiments into a coordinated effort, thereby significantly influencing the pace of innovation and the success of the overall research program.