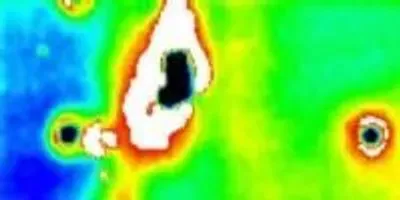

ORNL’s Ralph Dinwiddie uses infrared cameras to create heat maps of working materials that reveal their thermal properties and subsurface structure. This 1998 image of an aging aircraft’s engine cowling revealed severe subsurface corrosion.Image credit: Oak Ridge National Laboratory, U.S. Dept. of Energy; Ralph DinwiddieScientists at the Department of Energy’s Oak Ridge National Laboratory are pioneering the use of infrared cameras to image additive manufacturing processes in hopes of better understanding how processing conditions affect the strength, residual stresses, and microstructure of 3D-printed parts. This is just the latest application to build upon decades of expertise in IR cameras that have added scientific understanding to promising technological developments.

ORNL’s Ralph Dinwiddie uses infrared cameras to create heat maps of working materials that reveal their thermal properties and subsurface structure. This 1998 image of an aging aircraft’s engine cowling revealed severe subsurface corrosion.Image credit: Oak Ridge National Laboratory, U.S. Dept. of Energy; Ralph DinwiddieScientists at the Department of Energy’s Oak Ridge National Laboratory are pioneering the use of infrared cameras to image additive manufacturing processes in hopes of better understanding how processing conditions affect the strength, residual stresses, and microstructure of 3D-printed parts. This is just the latest application to build upon decades of expertise in IR cameras that have added scientific understanding to promising technological developments.

In 1995, DOE’s Continuous Fiber Ceramic Composite program, led by ORNL, bought a high-speed IR camera—one of the first available for purchase outside the military. ORNL researcher Ralph Dinwiddie used the new IR camera to help developers of tough, lightweight ceramic composites study how well these materials conducted heat and use the insight gained to optimize manufacturing processes.

Related article: Annihilating Nanoscale Defects

Since then, ORNL has acquired at least ten additional IR cameras for use in a spectrum of other projects. The cameras have mapped changing temperatures as heat flows through objects from gears to artwork.

“At first we just planned to use this camera to measure thermal diffusivity maps of composites,” Dinwiddie said of the 1995 purchase. “This would allow us to measure the constituent properties and to study how they changed due to the processing conditions.”

Thermal models of the time were inadequate at predicting the thermal conductivity of composites based on the properties of their starting materials. Dinwiddie argued this was because material properties changed as a result of exposure to high temperatures and/or pressures during processing. Thermography became a new way to probe ceramic matrix composites, which were produced when ceramic fibers were surrounded by a protective coating and then embedded in a ceramic matrix. “Information on the constituent properties after processing allows better modeling of future composites,” Dinwiddie said.

Related article: New Research Could Help Build Better Fighter Planes and Space Shuttles

Materials developed under the CFCC program made their way into a land-based gas turbine for power generation, placed into operation at Malden Mills in Massachusetts in 1999, with the lowest emissions of any industrialized heat and electric combined facility in the United States.

Rick Lowden, the ORNL technical lead of the CFCC program, calls Dinwiddie’s IR camera “one of the best investments we ever made.” Dinwiddie and his colleagues moved on to use the camera to detect flaws below a material’s surface without destroying the sample. Such nondestructive testing could reveal, for example, hidden corrosion in aging aircraft, a bad pipe weld, pore formation deep inside a material or separating layers in a laminated composite.

Soon researchers from government, academia and industry were bringing additional materials to ORNL for infrared imaging. They gained access to Dinwiddie’s camera through the High Temperature Materials Laboratory user program, which made expertise and equipment available to companies that needed these resources to accelerate scientific and engineering insights that would improve their global competitiveness.

Related article: A New Material that Could Revolutionize Electronics

“Working with Ford Scientific Research Labs, we demonstrated the ability to strobe the IR camera to freeze the motion of brake discs during dynamometer testing, allowing us to produce temperature maps showing how hot spots developed and moved during braking,” Dinwiddie said of one project. “This combination of property mapping, temperature mapping, nondestructive testing, microscopic temperature measurement and process monitoring greatly expanded the demand for thermography services into a diverse array of applications.”

Indeed, other IR imaging projects have examined the impact behavior of lead-free, powder-metal bullets, calibrated micro-heaters, nondestructively examined nuclear fuel rods, assured the quality of lithium battery electrodes and separators and advanced prototypical runway lighting using alternate technologies and materials.