Modern microscopy facilities require rigorous adherence to safety protocols to mitigate the unique risks associated with high-resolution imaging of biological samples. Ensuring safety regarding both cryogen use and biohazard management in microscopy labs is fundamental to protecting researchers and maintaining the integrity of sensitive instrumentation. Laboratory professionals must balance the technical requirements of advanced imaging techniques, such as cryo-electron microscopy (cryo-EM) and cryo-electron tomography (cryo-ET), with stringent occupational health standards to prevent accidental exposure or equipment failure.

Managing primary cryogen risks and oxygen safety in imaging facilities

Managing cryogen risks requires a combination of continuous atmospheric monitoring, specialized pressure-relief systems, and rigorous ventilation protocols to prevent oxygen deficiency. In the context of cryo-electron microscopy, liquid nitrogen and liquid ethane are frequently employed to vitrify biological samples at temperatures below -150°C. These substances pose a physical hazard due to their extreme temperature and their ability to displace breathable air rapidly.

Liquid nitrogen expands by a factor of 694 when transitioning from a liquid state to a gas at room temperature. Even a minor leak in a poorly ventilated room can drop oxygen levels below the 19.5% threshold required for human safety. Consequently, oxygen deficiency monitors are essential in any room where bulk storage or high-volume usage occurs.

Liquid ethane presents an additional flammability risk that requires specialized handling compared to inert nitrogen. While ethane is essential for achieving the high cooling rates necessary to prevent crystalline ice formation, it has a lower explosive limit (LEL) of approximately 3% in air. Laboratory professionals must use ethane only within certified fume hoods or specialized vitrification enclosures that provide adequate spark-proof ventilation.

Proper storage of these substances requires high-vacuum insulated containers, known as dewars, which must be inspected regularly for "sweating" or ice formation on the outer shell. Such symptoms often indicate a breach in the vacuum insulation, which can lead to rapid pressure buildup and potential vessel failure. According to the Occupational Safety and Health Administration (OSHA), any area where large volumes of cryogens are stored must have a documented emergency response plan that accounts for these physical hazards.

Effective biohazard containment for high-resolution imaging suites

Effective biohazard containment in microscopy labs is achieved through the use of primary barriers, such as biosafety cabinets, and secondary engineering controls that maintain directional airflow. When imaging live or fixed pathogenic samples, the microscope itself must often be housed within a Biosafety Cabinet (BSC) or a specialized environmental enclosure. These setups maintain a negative pressure environment to prevent the escape of airborne contaminants.

The level of containment required is determined by the Biosafety Level (BSL) of the agent. Researchers typically refer to the Centers for Disease Control and Prevention (CDC) guidelines found in the Biosafety in Microbiological and Biomedical Laboratories (BMBL) manual. This manual provides a framework for categorizing pathogens based on their risk to laboratory workers and the surrounding community.

Aerosol generation is a significant concern during sample preparation and loading, particularly when using high-speed mechanical tools. For instance, the use of high-pressure freezers or automated plunge-freezers can create micro-droplets that carry biological contaminants if the sample is not properly sealed. Laboratory staff must ensure that all sample carriers and grids are handled within controlled environments to minimize the risk of environmental contamination during the transfer process.

Standard operating procedures (SOPs) must clearly define the steps for decontaminating sensitive optical components without compromising their functional integrity. Many common disinfectants, such as high-concentration bleach, can corrode lens coatings or delicate mechanical stages over time. Laboratory professionals often refer to the World Health Organization (WHO) Laboratory Biosafety Manual for guidance on selecting appropriate chemical germicides, such as 70% isopropyl alcohol or specialized quaternary ammonium compounds, that balance efficacy with equipment compatibility.

Mandatory PPE for cryogen and biohazard handling

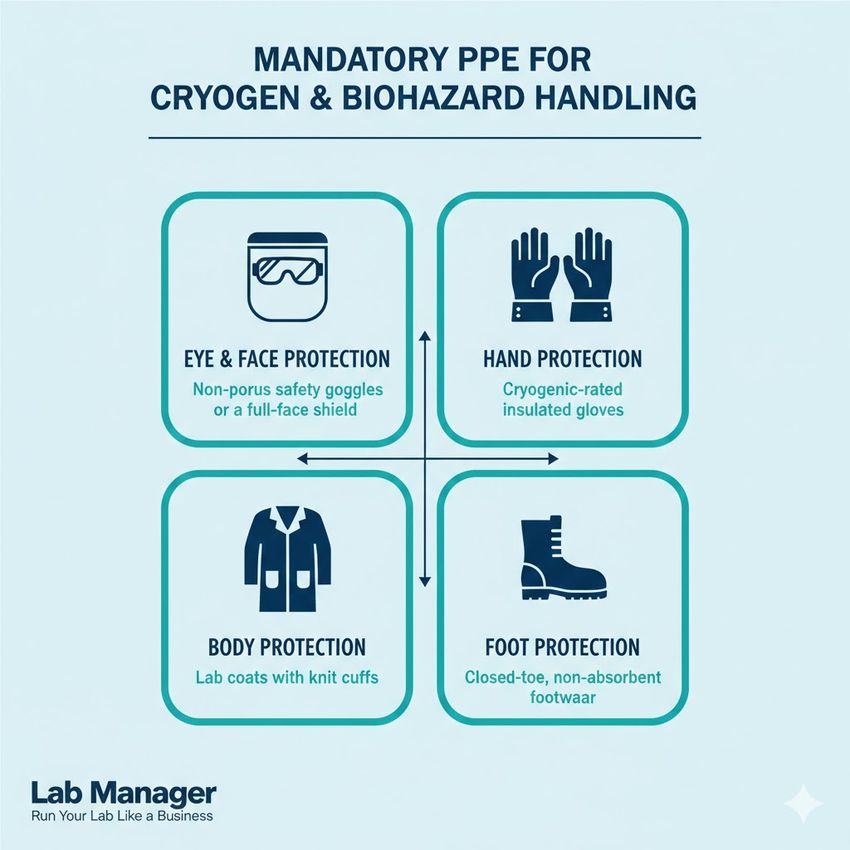

Mandatory personal protective equipment (PPE) for microscopy labs must protect against both extreme thermal burns and accidental exposure to infectious biological agents. Because standard medical gloves provide no protection against cryogenic temperatures and can actually freeze to the skin upon contact, specialized cryo-gloves must be worn during bulk liquid transfers. However, these gloves are often bulky and should be swapped for nitrile gloves when performing fine manipulations of biohazard samples to maintain necessary manual dexterity.

The selection of PPE should be based on a comprehensive risk assessment that considers the volume of the cryogen being handled and the pathogenicity of the sample. For high-risk procedures like manual plunge-freezing, the following items are considered mandatory:

Safety first: Ensure your team is protected with the essential PPE required for handling cryogens and biohazards, from insulated gloves to non-porous face shields.

GEMINI (2026)

- Non-porous safety goggles or a full-face shield: Protects the eyes and mucous membranes from both cryogenic splashes and biological aerosols.

- Cryogenic-rated insulated gloves: Designed to withstand temperatures as low as -196°C; these should be loose-fitting to allow for rapid removal if liquid enters the glove.

- Lab coats with knit cuffs: Prevents liquids from running down the arms and provides a barrier against low-level biological splashes.

- Closed-toe, non-absorbent footwear: Protects the feet from spills; perforated shoes or sandals are strictly prohibited in the presence of cryogenic liquids.

Regular inspection of PPE is essential to ensure that materials have not become brittle or porous over time. Protective gear that shows signs of cracking, thinning, or contamination must be decommissioned and replaced immediately to prevent accidental exposure. Following the American National Standards Institute (ANSI) Z87.1 for eye protection ensures that the equipment meets the impact and splash resistance necessary for high-intensity lab work.

The importance of integrated monitoring for facility safety

Integrated monitoring systems enhance safety by providing real-time environmental data that can detect both cryogen leaks and biosafety containment breaches before they escalate. Many facilities house pressurized gases, cryogenic dewars, and incubators for biological cultures. This arrangement creates a complex web of overlapping risks that require centralized oversight.

A failure in one system, such as a power outage affecting a -80°C freezer, can lead to both sample loss and a potential biohazard leak. This risk increases significantly if the sample integrity is compromised during the thaw. Modern facilities utilize networked sensors that track oxygen levels, ambient temperature, and airflow velocity within the imaging suites.

These systems are often connected to centralized Building Management Systems (BMS) to ensure immediately notification of safety personnel. Alerts are delivered via mobile devices or audible alarms to ensure a rapid response. Continuous monitoring reduces the reliance on manual checks and provides an indispensable audit trail for regulatory compliance during institutional inspections.

Data from the National Institutes of Health (NIH) suggests that automated alerts significantly decrease the response time during laboratory emergencies. By integrating these safety streams, labs can ensure that a cryogen leak does not lead to a secondary biohazard event. For example, a leak should not compromise a pressure-controlled room that relies on stable environmental conditions. Advanced systems can even trigger automatic emergency ventilation if oxygen levels drop below a pre-set safety margin.

Best practices for safe sample vitrification

Safe sample vitrification relies on standardized equipment use and the strict containment of flammable cryogens within high-exhaust environments. Liquid ethane is often used during vitrification because of its superior cooling rate. However, its flammability requires strict adherence to ventilation protocols to prevent the buildup of hazardous vapors.

Lab professionals must ensure that ethane stations are located away from ignition sources, such as vacuum pumps or hot plates. These stations should be properly exhausted through a high-efficiency particulate air (HEPA) filter if biological agents are involved. Standardizing these layouts reduces the chance of accidental fire or contamination during the high-speed cooling phase.

To minimize exposure, many labs have transitioned to automated vitrification systems that standardize the cooling process and reduce human error. These devices reduce the manual handling of liquid nitrogen and ethane, thereby lowering the risk of splashes and accidental skin contact. Furthermore, these systems often include enclosed chambers that help contain any biological aerosols generated during the high-velocity "plunge" phase into the cryogen.

Consistent training is the cornerstone of vitrification safety and must be refreshed annually for all laboratory personnel. Personnel must be proficient in the use of specialized tools, such as anti-capillary tweezers and grid boxes. These tools are designed to function reliably at extreme temperatures without becoming brittle. Peer-reviewed literature, such as that found in the Journal of Structural Biology, emphasizes that standardized sample preparation not only improves data quality but also enhances operator safety by reducing the time spent in high-risk zones.

Preventing cross-contamination in sensitive imaging environments

Cross-contamination prevention in microscopy labs requires the strict separation of "clean" and "dirty" workflows through designated zoning and dedicated equipment for different biosafety levels. Every piece of equipment, from pipettes to the microscope stage, must be subject to a validated cleaning protocol before and after use with biological agents. The use of disposable liners, specialized sample holders, and clear labeling of biohazard-only areas prevents the accidental transfer of pathogens between disparate research projects. Furthermore, air filtration systems, such as HEPA filters, should be regularly tested to ensure that the air exchange rates meet the necessary standards for the specific BSL of the lab. Institutional biosafety committees (IBC) typically require that these workflows be documented in a site-specific safety manual that is accessible to all researchers.

Conclusion: optimizing safety protocols for high-resolution imaging

The successful management of cryogen and biohazard risks in microscopy labs requires a multifaceted approach involving engineering controls, rigorous training, and consistent adherence to institutional protocols. By understanding the physical properties of cryogenic liquids and the infectious potential of biological samples, laboratory professionals can create a resilient environment that supports high-level research without compromising safety. Evidence-based practices, supported by guidelines from OSHA and the CDC, provide the framework necessary for maintaining these complex facilities. Ultimately, safety in advanced microscopy is an ongoing process of assessment, monitoring, and continuous improvement.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.