Informatics

At IDBS, our sights are firmly set on enabling collaboration, helping research and development (R&D) organizations gain greater insight from their data and getting their products to market quicker. So we asked ourselves how we could make this simpler. With E-WorkBook 10, not only will you have the power and performance you’ve come to expect from E-WorkBook, you’ll also discover the simplicity and ease of use that comes from an intuitively designed interface, and the flexibility and mobility that comes from our web-based spreadsheet technology.

Big data is the current hot buzzword in data analysis. Laboratory managers helming such a project don’t necessarily require the expertise to directly implement a big data project, but it is advisable that they have a general understanding of the process to be able to set realistic goals and timetables.

At IDBS, our sights are firmly set on enabling collaboration, helping research and development (R&D) organizations gain greater insight from their data and getting their products to market quicker. So we asked ourselves how we could make this simpler. With E-WorkBook 10, not only will you have the power and performance you’ve come to expect from E-WorkBook, you’ll also discover the simplicity and ease of use that comes from an intuitively designed interface, and the flexibility and mobility that comes from our web-based spreadsheet technology.

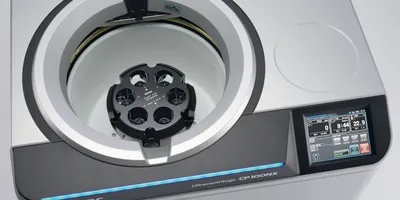

Knowing how instruments are utilized throughout your laboratory is important information to help you optimize operations, drive cost savings and improve productivity. However, capturing information on instrument ultilization in a lab comprised of an array of different manufacturers, techniques, control software and computer platforms presents a difficult challenge. Until now.

Rapidly growing firm ditches paper notebooks to boost collaboration, traceability and quality of data.

A Laboratory Information Management System (LIMS) serves as the interface to a laboratory’s data, instruments, analyses, and reports. For many analytical laboratories, a LIMS is an important investment that assists management in evaluating the efficiency of the laboratory’s operations and reducing costs.

Problem: Many service or contract laboratories need to process the same sets of samples on a regularly-scheduled basis. In addition, many processes within factories of various types require collection of samples at pre-set dates and times to ensure the quality of the product being produced. One example is collection of air and surface samples to test the sterility of rooms used in the production of pharmaceuticals, foods, and medical devices. Another example is collection of samples during beer production. The task of logging these samples into a LIMS (laboratory information management system) can be cumbersome and time-consuming and it is easy to miss collection of a scheduled sample. Although these are two entirely different scenarios, both require the same basic scheduling of multiple sample collections.

Most food producers are subject to a broad range of regulations and standards, from industry-wide ones such as ISO 22000 (which sets out several communications and system management guidelines), the United States Food Safety Modernization Act (FSMA) of 2011 and the European Union Regulation (EC) No. 178/2002 to process-specific ones like the Egg Products Inspection Act (EPIA) or the Federal Meat Inspection Act (FMIA).

Problem: There has been an explosion in the growth of information. So much growth, that traditional informatics solutions are no longer sufficient. The labs of today, and most certainly the labs of tomorrow, need new tools to gather the data generated, make sense of it and turn it into actionable knowledge.